CURRERA-R – Smart camera with PC inside

CURRERA-R is a range of Machine Vision Smart Cameras based on standard INTEL Atom CPU Personal Computer (PC) and packed

Read MoreCURRERA-R is a range of Machine Vision Smart Cameras based on standard INTEL Atom CPU Personal Computer (PC) and packed

Read MorePQCS.net Plate Quality Control System Druckplatten PrüfsystemDer Stillstand einer Druckmaschine ist bei den heutigen knappen Produktionszeiten bei Druckerzeugnissen aus wirtschaftlicher

Read MoreEttlingen – Vision Components introduces a right-angle head adapter which tilts the viewing direction of Smart Cameras by 90°. Thus, the integration of the already very small image processing systems into various industrial applications with limited installation space becomes even easier.

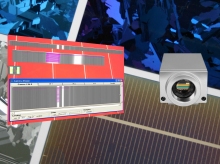

Ettlingen – For especially demanding machine vision applications, Vision Components supplies the VC4467/NIR, a highly sensitive image processing system in the shape of a barely fist-sized camera. VC4467-type cameras feature an EXview HAD CCD sensor from Sony which detects both visible light waves and long wave light near the infrared spectrum. They ensure very precise image recording even in low-light conditions. The new VC4467/NIR’s sensor has been modified in order to further increase sensitivity in the near infrared range; as a result, the camera supplies high-quality data at wavelengths up to 1,100 nm. The camera is thereby optimally suited for tasks such as electroluminescence (EL) quality control in the photovoltaic industry. Monitoring the production of solar cells, it reliably detects and identifies defects such as micro cracks, shunts, and disconnected fingers. The intelligent NIR camera also meets all requirements for night-time use. Even at a distance, image capture is effective.

The VC4002L line scan camera from Vision Components controls laser scribing of thin-film solar cells, i.e. the separation of conducting paths. The cells’ substrate material, e.g. glass, is coated with a thin silicon film which is then structured by a laser. The conducting paths run in parallel and as close as possible without touching. The monitoring system checks the P1, P2, and P3 scribes and controls the laser in real-time with a precision of 1 µm. The sensor scans the laser line position at a 5 ms rate, providing 200 measurements per second. All data can be read out directly from the camera via an Ethernet or RS232 interface.

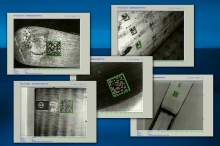

Ettlingen – The VC Smart Reader from image processing expert Vision Components is a first-rate software solution for data matrix code recognition. Combined with the company’s intelligent cameras, the VC Smart Reader enables quick and reliable identification of 2D codes – depending on the camera model, it provides a maximum frame rate of 150 fps. Code detection and reading is not affected by the code’s shape and size, the orientation of the code (which can be rotated by 360°), or by the background type (dark-on-bright or bright-on-dark). Advanced image noise reduction enables consistent detection even when codes are heavily damaged or when there are intense background interferences. Mirrored codes are reliably identified and read, just as special code types, such as nailed or dotted codes. Furthermore, results are not impaired by a covered „L“ corner or a partially destroyed „L“ pattern of the Data Matrix code.

Ettlingen – Vision Components has extended the VC nano camera series, adding various new models for many applications. Optionally available as single board cameras or with a protective enclosure, the cost-efficient nano cameras are based on a board that is populated on both sides, thereby reaching ultra-compact dimensions of 40 x 65 mm or 80 x 45 x 20 mm. A new hardware variant further facilitates integration: various models are available with a remote camera head measuring merely 22 x 22 x 19,5 mm, which ensures optimal installation flexibility thanks to a connection cable that can be several meters long. Moreover, VC now also supplies an IP68 enclosure for all nano cameras, including lenses and lighting, which allows for use in rugged industrial environments. The new models VC6211 nano / VCSBC6211 nano, which are particularly sensitive for light in the near infrared range, are especially suitable for applications in outside areas.

Point Grey, a world leader in advanced imaging products, today announced the launch of its Gazelle Camera Link digital camera series, delivering an unsurpassed combination of size, speed and price.

The Gazelle camera debuts with 2.2 and 4.1 megapixel monochrome models that are based on the high sensitivity CMOSIS CMV2000 and CMV4000 global shutter CMOS sensors. With a Camera Link digital interface in Base (2-tap) and Full (8-tap) configurations, the 2.2 megapixel model outputs 2048×1088 resolution images at a maximum rate of 280 FPS, while the 4.1 megapixel model outputs 2048×2048 images at 150 FPS. The Gazelle features the same compact housing as Point Grey’s popular Grasshopper camera, which measures just 44 x 29 x 58 mm in size. A host of features are included for customizing imaging applications, including opto-isolated GPIO for industrial triggering and strobe output, pixel binning and region of interest modes, and user configuration sets for custom default settings.

Mit der Akquisition stärkt AVT ihre Position als führender Hersteller von Industriekameras im Weltmarkt.

AVT-Zentrale in Stadtroda

VDS-Vosskühler Firmensitz in Osnabrück

Allied Vision Technologies, Marktführer im Bereich der digitalen Gigabit Ethernet und FireWire Industriekameras, übernimmt rückwirkend zum 1. Januar 2011 den in Osnabrück ansässigen Kamerahersteller VDS Vosskühler zu 100%. Mit der Akquisition erweitert Allied Vision Technologies ihr Produktangebot um die zukunftsträchtigen Nahinfrarot- (NIR) und Langwelleninfrarot- (LWIR) Technologien, sowie um umfangreiche Kompetenzen im Bereich der aktiven Kamerakühlung und baut somit ihre führende Marktposition im Bereich digitaler Industriekameras weiter aus.

Factory Automation (Machine-Vision) Mini Lens with very low distortion, M12-Mount (S-Mount)

Read More